What is a thermocouple sensor?

In the world of commercial food service, precision and reliability in measuring the temperature of dishes and ingredients is crucial to quality and safety. Whether you’re running a restaurant, managing a food processing plant, tracking temperatures in a laboratory, or ensuring food safety standards in a catering business, choosing the right temperature sensor can be a daunting task.

In the world of commercial food service, precision and reliability in measuring the temperature of dishes and ingredients is crucial to quality and safety. Whether you’re running a restaurant, managing a food processing plant, tracking temperatures in a laboratory, or ensuring food safety standards in a catering business, choosing the right temperature sensor can be a daunting task.

Among the options available, thermocouple probes stand out for their versatility, accuracy, and performance. But what exactly are thermocouples, and why might they be the ideal choice for your business? Read on to find out.

How do they work?

A thermocouple is a sensor made from two dissimilar metals joined together. This thermocouple junction creates a voltage that changes with temperature—and is then measured and converted to a temperature reading. Different metal combinations result in different thermocouple “types,” each suited for a specific temperature range and application.

What are the various types of thermocouples?

The most common type is the “K” thermocouple, used in general industry, science, and food. Others include:

- K-type (for general purpose, temperatures up to 2300°F)

- J-type (good for lower temperatures up to 1472°F)

- N-type (good for high temperatures up to 2300°F)

- T-type (good for lower temperatures up to 752°F)

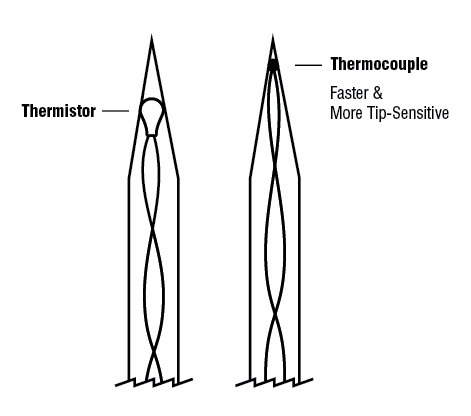

How are they different from thermistors?

How are they different from thermistors?

A thermistor sensor, made from semiconductor materials that change resistance with temperature, is typically less expensive and used in low-cost applications. Meanwhile, a thermocouple, made from two different metal alloys generating a voltage with temperature changes, offers a wider temperature range, faster response time, and higher accuracy.

Why choose a thermocouple sensor?

These sensors are widely used in commercial and professional thermometers due to several key benefits:

- Wide Temperature Range: Thermocouple probes can withstand a much wider temperature range than thermistors. Some type K probes can measure up to 2,200°F, while thermistors struggle with accuracy above 300°F.

- Fast Response: Thermocouples are smaller and respond to temperature changes faster than thermistors due to their simpler design (two wires vs. a bead and coating). This allows for faster and more precise readings.

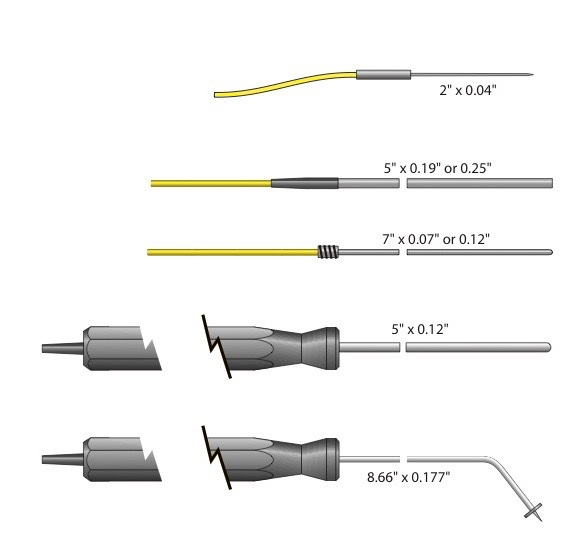

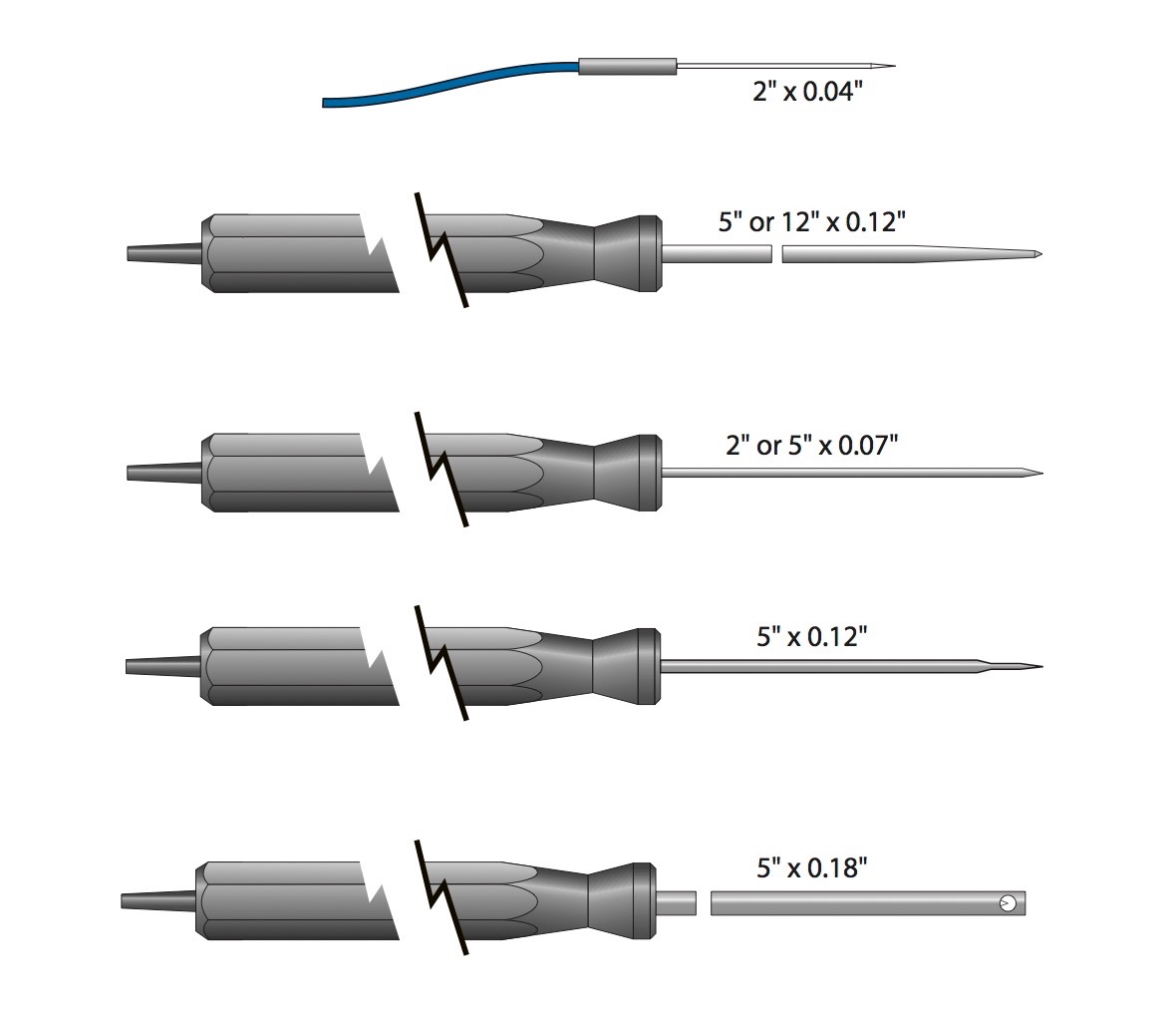

- Probe Design Flexibility: Thermocouples can be crafted into various shapes and sizes to fit specific needs. They can be incredibly thin for tight spaces or have heavy-duty wires for high-temperature environments.

- Accuracy: High-quality thermocouples are more precise (usually they’re better than ±0.9°F between 32°F and 212°F) compared to typical thermistors. This accuracy can be further improved with system calibration. (See our calibration services.)

- Cost: Thermocouples are generally less expensive than some scientific or commercial sensors. However, they may be slightly more costly than low-grade consumer thermistors due to the use of higher-quality materials.

To summarize: Thermocouples offer a compelling combination of affordability, wide temperature range, fast response, and accuracy. This makes them a versatile and valuable tool for various industrial, scientific, and even culinary applications.

SHOP THERMOCOUPLE PROBES

Styles of Type K Thermocouples

|

|

|

|

|

|

|---|

All ThermoWorks Temperature Probes

|

|

|

|

|---|